Cooling Tower Cleaning Services

Removing Harmful Contaminants In Your AC

Cooling towers play a crucial role in the air conditioning and industrial process systems at many facilities, but they must be properly maintained and regularly cleaned in order to operate properly. At Guardian Services, our full-scale method of cooling tower cleaning removes all scale, sediment, and organic nutrients, which can lead to bacterial growth and potentially serious health issues. To request a quote to get your cooling tower cleaned, call us at (214) 637-1520. We serve Dallas and the surrounding areas of North Texas.

Why Clean Your Cooling Tower?

Cooling towers are an efficient and cost-effective way to cool water for air conditioning and industrial processes. They use a fan to move air through a recirculating water system in an outdoor location. This process along with the exposure to the outdoor elements can lead to the buildup of scale, sediment, and biological contaminants. This buildup can result in the following:

- System degradation

- Loss of efficiency

- Potentially serious health issues

Regular maintenance of the tower and chemical treatment of the system’s water supply can help reduce these issues, but a full system cleaning is required to remove all contaminant buildup and ensure that the tower's components are operating efficiently.

How Often Does Your Cooling Tower Need Cleaned?

As per the Occupational Safety and Health Administration or OSHA, cooling towers should be drained and fully cleaned quarterly or at least twice a year. If a cooling tower is not used year-round, it should be cleaned before initial start-up, at the beginning of the cooling season, and after shut-down in the fall. Towers that show high levels of biological growth should be cleaned immediately and towers that have been out of service for long periods of time should be cleaned before they are put back in service. OSHA also recommends that new systems be cleaned and disinfected to remove construction residue, which can contribute to biological growth. Guardian Services performs free, photo-documented inspections for all customers and has certified air system cleaning specialists on staff to help you determine if you or your cooling tower can benefit from cleaning.

Our Cooling Tower Cleaning Process

Our team performs a full-scale cleaning of the cooling tower, which involves fully draining the system and cleaning the interior and exterior surfaces by manual and hydraulic means. This process includes cleaning the following:

- Cooling tower structure

- Casing

- Fans

- Pumps

- Piping

- Spray nozzles

- Fill

- Louvers

- Any other surfaces that show contaminant build-up

Guardian's cleaning process begins with a full system inspection to determine the specifics of the cooling tower, identify any issues or damaged areas, and formulate an effective cleaning plan. Our cooling tower technicians access the system in a safe and professional manner and protect all vulnerable components before starting the cleaning process. Once the system is drained, all sediment and debris are removed from the tower basin and collected for safe, off-site disposal. A non-hazardous chemical is used to treat all contaminated surfaces and the interior and exterior of the tower are scrubbed and power washed to remove all contaminants. Once the tower is entirely clean, it is re-inspected for any issues or damage and all components are returned to those settings recorded just prior to the cleaning operations.

Approach & Project Management

At Guardian Services, we always provide a thorough system assessment before starting any work to determine the best cleaning methods to use in order to protect the building occupants and equipment. Here are some things you can expect from our commercial systems cleaning services:

- Protective plastic sheeting is used to cover all vulnerable surfaces.

- All access points are re-sealed per code.

- Full performance checked.

- Technicians remove all the protective covers.

- Photo documentation is provided for all projects to document the before and after condition of the system and ensure all areas are properly serviced.

- Additional cleanliness testing can be performed where required.

For more information or to request a quote for cooling tower cleaning in Dallas, Addison, or Richardson, give us a call at (214) 637-1520. We also service commercial kitchen exhaust systems, laundry exhaust systems, and air duct systems.

Request QuoteOur Customer Portal

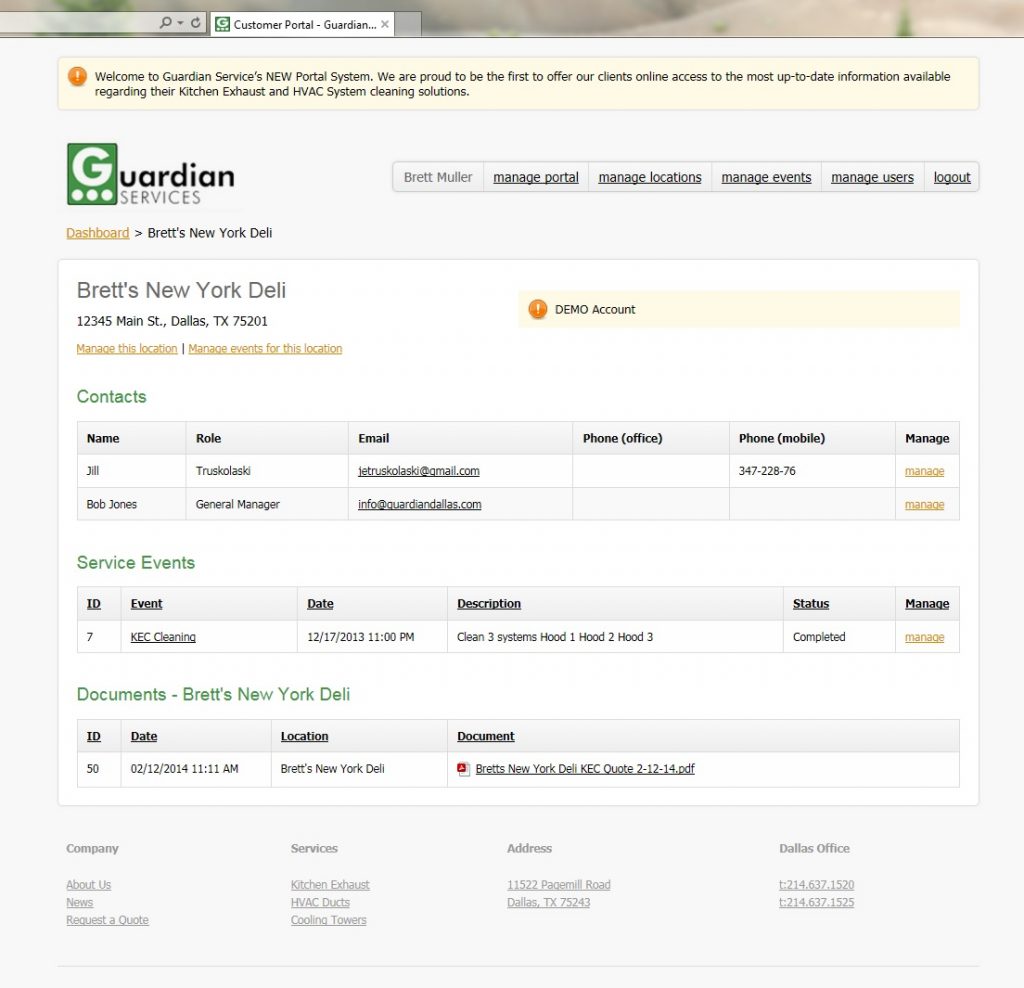

All Guardian customers will be given access to our customer portal system. The portal is open 24/7 for customers to access their documentation, scheduling, and photos.